Elevating Performance with Cerakote's Rigorous Trials

PRODUCT TESTING | Unleash the Power of Durability!

Cerakote, the leader in ceramic coatings, presents testing that surpasses expectations. We push products to extremes, from scorching heat to corrosive chemicals. Our coatings resist wear, corrosion, and impact, ensuring unmatched protection. Plus, vibrant colors endure, defying fading. Trust Cerakote for unrivaled durability.

Experience Cerakote Product Testing and witness the power of resilience.

Abrasion Test

Our Coatings Withstand the Toughest Challenges

Abrasion Testing pushes the boundaries of endurance, ensuring unparalleled resistance against wear and abrasion. Through meticulous testing, the coatings' ability to withstand friction, contact, and repetitive mechanical stresses is meticulously assessed, guaranteeing unwavering performance in the most demanding applications.

Rest assured that Cerakote coatings will triumph over the challenges of daily use, thanks to their proven ability to resist friction, impacts, and abrasive forces. The confidence bestowed by abrasion testing ensures that the coatings will endure and provide reliable protection and longevity, even in the most demanding environments.

Abrasion Test

Our Coatings Withstand the Toughest Challenges

Abrasion Testing pushes the boundaries of endurance, ensuring unparalleled resistance against wear and abrasion. Through meticulous testing, the coatings' ability to withstand friction, contact, and repetitive mechanical stresses is meticulously assessed, guaranteeing unwavering performance in the most demanding applications.

Rest assured that Cerakote coatings will triumph over the challenges of daily use, thanks to their proven ability to resist friction, impacts, and abrasive forces. The confidence bestowed by abrasion testing ensures that the coatings will endure and provide reliable protection and longevity, even in the most demanding environments.

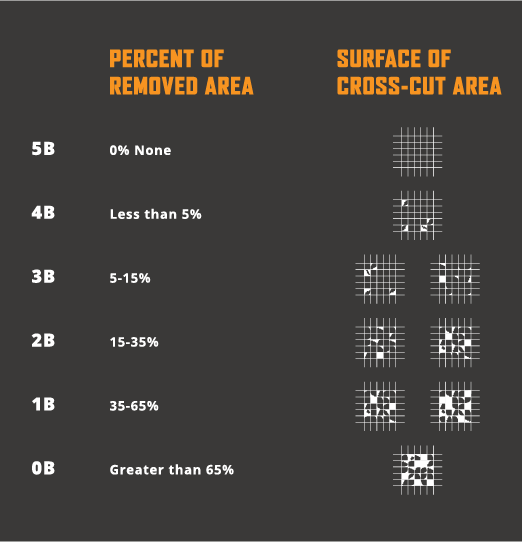

Adhesion

Unbreakable Bond for Uncompromising Performance

Adhesion testing is a critical process in Cerakote applications, ensuring a robust bond between the coating and the substrate. It assesses the strength and integrity of the coating's adhesion, ensuring long-lasting durability and performance.

During adhesion testing, various techniques such as crosshatch, pull-off, or tape tests are employed to evaluate the bond between the Cerakote coating and the underlying surface. These tests simulate real-world conditions and forces to determine the coating's ability to adhere firmly without peeling, flaking, or delaminating.

Adhesion testing in Cerakote not only guarantees the durability of the coating but also instills confidence in its performance. It ensures that the applied Cerakote will provide a long-lasting and dependable finish, offering superior protection and aesthetic appeal for firearms, automotive parts, and various other applications.

Chemical Resistance

Unyielding Protection Against Chemicals

Cerakote is renowned for its exceptional chemical resistance. Its ceramic-based coating, combined with a polymer matrix, creates a robust barrier that shields surfaces from corrosive substances, solvents, and extreme temperatures. This resistance preserves aesthetics, extends durability, and ensures easy maintenance. Cerakote's reliability in challenging chemical environments makes it a top choice for various industries.

Coating For Night Vision Camouflage

Coating For Night Vision Camouflage

Master the Shadows, Unseen and Unmatched

When it comes to night vision camouflage, specialized coatings play a crucial role in enhancing stealth and concealment. These coatings are designed to minimize the reflection of light in the infrared spectrum, effectively reducing the visibility of objects through night vision devices.

With the right coating, night vision camouflage can provide a significant advantage by allowing military personnel, law enforcement, or hunters to blend seamlessly into the darkness, remaining undetected by the enemy or wildlife. These coatings are carefully engineered to balance effectiveness, durability, and environmental adaptability, ensuring reliable performance in various operational conditions.

Color Measurement

Perfecting the Art of Precision Hue

Color measurement testing in Cerakote ensures precise and consistent color accuracy across various applications. This rigorous testing process involves using specialized equipment to assess the color properties of the coating, ensuring it meets the desired specifications.

By measuring parameters such as hue, saturation, and lightness, color measurement testing guarantees that Cerakote coatings exhibit uniform and reliable color reproduction. It enables manufacturers and applicators to maintain consistent color standards, whether it's for firearm finishes, automotive coatings, or other customized applications.

With color measurement testing, the visual appearance and aesthetic appeal of Cerakote coatings can be precisely controlled. It ensures that customers receive products with the intended color characteristics, while also providing quality assurance and customer satisfaction.

Durability

Durability

Defying Limits, Embracing Reliability

Cerakote durability testing pushes the limits of strength and resilience, ensuring exceptional performance in even the most demanding conditions. Through rigorous testing methodologies, Cerakote coatings are evaluated for their ability to withstand abrasion, impacts, chemicals, and extreme temperatures.

Durability tests assess the coating's resistance to wear, corrosion, and physical stress, guaranteeing its longevity and reliability. These tests simulate real-world scenarios, ensuring that Cerakote coatings maintain their protective properties and aesthetic appeal over time.

By subjecting Cerakote to durability testing, manufacturers and users can have confidence in its ability to endure the harshest environments and maintain its superior performance. Whether it's for firearms, automotive parts, or industrial equipment, Cerakote's durability ensures long-lasting protection and an enduring finish.

Hardness

Unveiling the Armor of Resilience

Pencil hardness testing is a widely used method for evaluating the hardness and scratch resistance of various coatings and surfaces. It involves the use of pencils with different hardness grades to determine the level of hardness that can cause visible marks or scratches.

During the test, a series of pencils with increasing hardness, ranging from 9H (hardest) to 9B (softest), are pressed against the surface under a specific load. The hardness of the pencil that leaves a visible mark indicates the coating's resistance to scratching and its overall hardness level.

Pencil hardness testing provides valuable insights into the durability and performance of coatings in real-world scenarios. It helps assess the coating's ability to withstand everyday wear, abrasion, and potential damage from objects or substances encountered in its intended application.

Multi Jet Fusion

Multi Jet Fusion

Embrace Unrelenting Performance Cerakote's Multi Jet Function Test

Multi Jet Function Test propels the coatings through a comprehensive assessment, scrutinizing their resilience against a spectrum of environmental challenges. This exhaustive testing procedure encompasses exposure to temperature fluctuations, moisture, chemicals, and UV radiation, ensuring that Cerakote coatings thrive in diverse conditions.

Cerakote's proven fortitude in the face of a multitude of stressors positions it as the premier choice for a myriad of applications, spanning firearms, automotive components, and industrial equipment. The Multi Jet Function Test instills confidence, assuring users that Cerakote coatings will consistently deliver flawless results across varying conditions, unleashing lasting functionality and reliability.

Outdoor Corrosion

Unyielding Protection Against Nature's Fury

Outdoor corrosion testing confirms the unparalleled resistance of the coatings against the elements, ensuring long-lasting protection in outdoor environments. Through exposure to harsh conditions like moisture, UV radiation, salt spray, and temperature fluctuations, these tests evaluate the coating's ability to withstand corrosion and degradation.

Cerakote's exceptional resistance to outdoor corrosion makes it a preferred choice for various industries, including firearms, automotive, marine, and outdoor equipment. It provides peace of mind that the coated surfaces will withstand the challenges posed by the elements, ensuring long-term protection and aesthetics.

Photopolymers

Photopolymers

Unleashing the Artistry of Unmatched Precision

Cerakote photo polymers testing is a crucial step in the manufacturing process, ensuring precise and consistent reproduction of intricate designs and patterns. This testing involves using specialized techniques to evaluate the quality and resolution of the photo polymer image transfer process.

By subjecting Cerakote coatings to photo polymers testing, manufacturers can verify the accuracy and clarity of the transferred images. This ensures that the final product maintains the intended level of detail, sharpness, and visual impact.

Photo polymers testing guarantees that Cerakote coatings achieve exceptional image fidelity, even on complex surfaces. It enables the replication of logos, graphics, camouflage patterns, and other intricate designs with consistent quality, meeting the high standards of various industries and applications.

Salt Spray Corrosion Test

Unwavering Protection in Salty Seas

Cerakote Salt Spray Corrosion Testing pushes the boundaries of protection, ensuring unrivaled resilience against the corrosive forces of saltwater environments. By subjecting the coatings to an intensive saltwater mist, this test simulates the harsh conditions found in coastal and marine settings.

Through salt spray corrosion testing, Cerakote coatings demonstrate their exceptional ability to withstand prolonged exposure to saltwater, effectively preventing corrosion and preserving the integrity of the coated surfaces. This testing guarantees that the coatings maintain their unwavering protective properties, color stability, and overall performance, even in the face of relentless corrosive challenges.

With Cerakote's remarkable resistance to salt spray corrosion, it becomes the go-to choice for marine applications, outdoor equipment, and coastal environments. Feel confident that your surfaces will remain shielded from corrosion, no matter how unforgiving the saltwater environment may be.

Frequently Asked Questions

Hi there! Have some questions about our company? Find the answers below.

-

Why is Southern Eagle Tactical so popular?

Southern Eagle Tactical is a firearm shop located in Waynesboro, TN. Our massive collection of firearms, military surplus, ceramic coatings, and cerakote is sure to meet the needs of gun lovers and military enthusiasts everywhere! You won't find a more impressive and unique selection of firearms or military surplus items anywhere else. We guarantee it!

When you need the perfect firearm, Southern Eagle Tactical will deliver. Our team of firearm experts has years of experience and will use their extensive knowledge of firearms to supply you with the best products available. We take pride in offering high-quality firearms at fair and reasonable prices. Whether you need a new shooting rifle or something for your concealed carry, our firearm experts can assist you in finding a firearm that fits you perfectly.

We also offer high-quality ceramic coating and cerakote options for customer firearms at unbeatable prices. Whether you're looking for a more typical design or a custom art piece, we can get the job done for you promptly.

-

What products do you offer?

Southern Eagle Tactical offers high-quality firearms, military surplus items, ceramic coating for customer firearms, and cerakote options for your pieces.

Visit our online shop today to view our inventory of products and find the products that match your unique style and needs.

If you have any questions or concerns, please call us at 931-722-7181. Or you can submit one of the contact forms on our website. We can't wait to assist you with your firearm, military surplus, ceramic coating, and cerakote needs!

-

Can you perform custom ceramic coating and Cerakote jobs?

Yes, we can! At Southern Eagle Tactical, our firearm experts are well-versed in ceramic coating and cerakote techniques. Our team has years of experience and aims to provide the most exceptional designs and coating projects possible. We understand how vital having a unique firearm is and pay attention to details when coating your piece.

To learn more about our custom ceramic coating and Cerakote options, please call today at 931-722-7181. You can also contact us by submitting one of the contact forms on our website. We can't wait to assist you in customizing your firearm and bringing your artistic vision to life!

-

What is the best method of contact?

Southern Eagle Tactical can be reached by phone at 931-722-7181, by email at jeff@southerneagletactical.com, or by submitting one of the contact forms on our website.

When you contact our team, you can expect fast and friendly assistance with all your firearm, military surplus, ceramic coating, and cerakote-related needs.

Call:

Email:

Address:

Newsletter Sign Up

Contact Us

Thank you for subscribing!

You will receive our latest product promotions & Sale notifications in your email.

Please try again later.

All Rights Reserved | Southern Eagle Tactical